Ford has $200 million tied up in inventory, while Tesla has none. Why the difference?

The answer lies in modern manufacturing and on-demand production—principles that Tesla has embraced and the automotive industry is slowly catching up to. The eyewear industry faces the same inventory problem that Ford once did.

The Eyewear Industry’s Outdated Manufacturing Model

Frame manufacturing, like automotive production, has been stuck in the 1960s.

- Unreliable human labor

- Costly molds

- Antiquated manufacturing processes

These traditional methods create significant inefficiencies:

- 3-4 month lead times

- High minimum order quantities (MOQ)

- And, most importantly, huge amounts of waste.

Brands are left holding onto unsold inventory, with as much as 20% of stock ending up as dead stock at the end of the year.

This means eyewear brands are:

- Tying up huge amounts of capital in inventory.

- Spending significant amounts on storage, transportation, and distribution.

- Watching their stock depreciate, with much of it remaining unsold.

How 3DNA Solves the Problem

Just like Tesla revolutionized manufacturing with digital, on-demand production, 3DNA brings this concept to eyewear.

- Digital, on-demand manufacturing means no more dead stock.

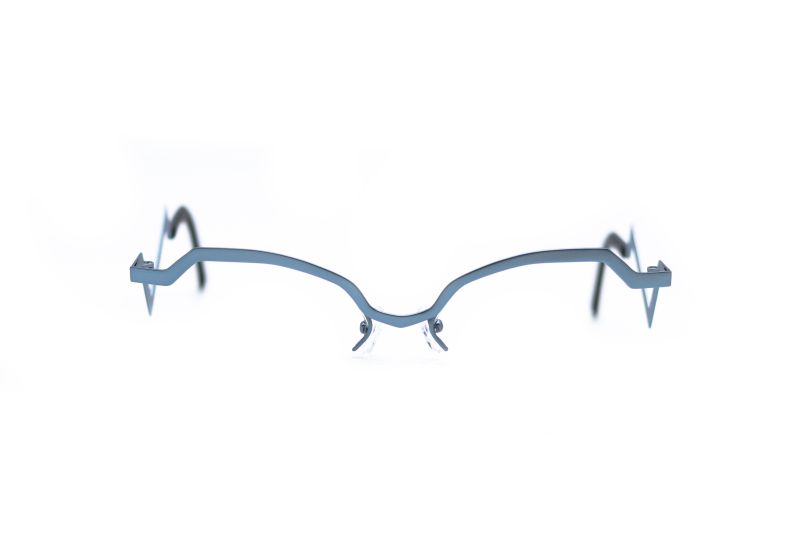

- Customizable frames: If the size or color doesn’t work, it’s easy to fix—because production is tailored to customer needs, on-demand.

- Brands can exit the inventory and logistics business, freeing them to focus on design and marketing.

A Proven Model

Just like digital lenses, which are produced on-demand by labs using a licensing model, eyewear manufacturing can operate the same way:

- No stock.

- No inventory.

- Less carbon footprint.

- Eyewear personalized to individual dimensions and preferences.

The Future of Eyewear Manufacturing: On-Demand and Sustainable

Looking to onshore frame manufacturing? Add high-value personalization to digital lens production?

The future of the eyewear industry is about flexibility, sustainability, and efficiency—and 3DNA is here to help you lead the way.

Get ready. Get set. Get 3DNA.

Revolutionize your eyewear production, reduce waste, and eliminate inventory problems for good.