Eyewear brands and distributors are tied up with huge costs and capital due to a deeply rooted, outdated production model.

Why is this happening?

- Large Minimum Order Quantities (MOQs): Eyewear brands must place large orders to meet factory requirements, leading to excess inventory.

- Long Production Times: Frames take 3-4 months to produce, with another month for sea shipping.

- Big Inventory Costs: Brands and distributors make one or two big orders per year, tying up cash in inventory, logistics, and storage.

- Wasted Stock: At the end of the year, about 20% of stock remains unsold, often ending up in landfills.

This mass production mindset is deeply ingrained, but it’s causing inefficiencies, waste, and capital mismanagement.

A Better Way: Digital Transformation

Switching from batch production to continuous flow production brings significant benefits:

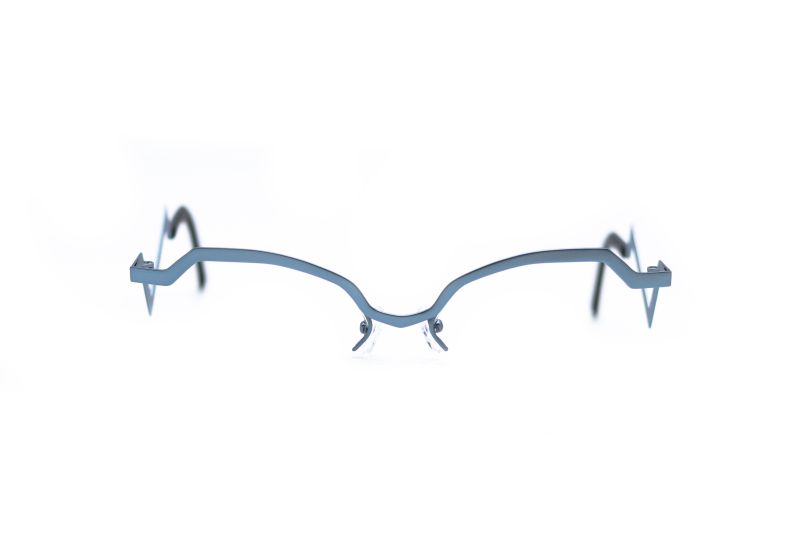

- No Molds or Associated Costs: Traditional molds are costly and require significant upfront investment. With digital production, these costs are eliminated.

- No Minimum Order Quantities: Order as little as you want—eliminate the need for bulk orders.

- Shortened Production Times: Instead of waiting months, frames can be produced in just a few days.

- On-Demand Production: Production is “just in time,” allowing for personalization in color, shape, and design, based on customer preferences.

This model has been proven in other industries, like progressive lenses, and companies like Tesla already embrace the zero-inventory model.

Key Benefits:

- Optimized Cash Flow: Only produce after a sale, conserving capital and reducing depreciation.

- Reduced Carbon Footprint: By cutting down on transportation and waste, digital production helps make eyewear more sustainable.

- Personalization: Customization in design and sizing meets the unique needs of every customer.

Why is the Eyewear Industry Hesitant?

Despite the clear advantages of digital production, many in the legacy eyewear industry are still hesitant. They view this shift as something for the far-off future, but it’s already here—and it’s happening now.

The Opportunity: Be a First Mover

The first eyewear brands to adopt this digital transformation stand to gain early market share. The shift from traditional, mass-produced eyewear to on-demand, personalized eyewear is inevitable—and those who act fast will lead the charge.

3DNA is here to help you navigate this change, from desktop production at bespoke ateliers to fully automated digital production lines.

Take the Next Step

Are you ready to be a part of the green, sustainable future of eyewear?

Send us a message, book a call, or download our app to experience the benefits of on-demand eyewear for yourself.

The future is already here—and 3DNA can help you get there today!