Eyewear brands and distributors are facing huge costs and tied capital because traditional frame production requires large Minimum Order Quantities (MOQs). Here’s why:

- Production time: 3-4 months, plus an additional 1 month for sea shipping.

- Big orders: Brands and distributors are forced to place 1-2 large orders per year, locking up cash and capital.

- Logistics and storage: These add unnecessary costs to the overall inventory expense.

- Dead stock: At the end of the year, approximately 20% of inventory remains unsold or ends up in landfills.

The Mass Production Mindset

For years, the eyewear industry has been stuck in a mass production model deeply rooted in factory traditions. However, digital transformation offers a better solution.

A Better Way: Digital Transformation

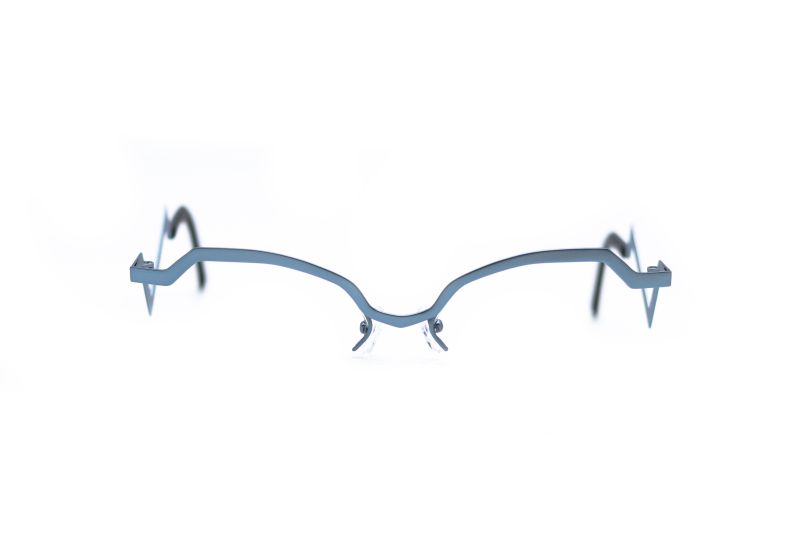

- Continuous flow production: This eliminates the need for molds and the associated costs.

- No MOQ: Say goodbye to the limitations of minimum order quantities.

- Faster production: Instead of waiting for months, frames can be produced in days.

- Just-in-time production: This allows for modifications like shape and color, creating more flexibility.

Proven Success in Other Industries

Industries like progressive lenses and even Tesla have proven the effectiveness of on-demand production and zero-inventory models. In these models:

- Products are made only after the consumer places an order.

- Capital is conserved and depreciation is reduced.

- Personalization becomes possible without huge upfront investments.

By eliminating unnecessary waste and lowering the carbon footprint, this modern approach is much greener and more sustainable.

The Opportunity for the Eyewear Industry

Despite all the advantages, the legacy eyewear industry is hesitant to adopt digital fabrication, often viewing it as something for the far-off future. However, this reluctance creates a massive opportunity for first movers to capture early market share.

Get 3DNA: The Future of Eyewear Production

With 3DNA, we are revolutionizing the eyewear industry through digital transformation—from desktop production to fully automated lines.

Interested in Learning More?

The future is already here—it’s just unevenly distributed.

Be a part of the solution and get 3DNA today. Let’s move toward a greener, more sustainable future.