In a world where personalization is no longer a luxury but an expectation, industries built on mass production are being pushed to evolve. The eyewear industry, traditionally dominated by mass manufacturing, is no exception. Recognizing this shift early, 3DNA Technology emerged in 2014 with a mission to reshape the future of eyewear through advanced technological innovation. By 2018, the company had officially incorporated and begun laying the foundation for a transformative solution to one of the industry’s most persistent challenges—mass production inefficiencies.

Understanding the Problem: The Cost of Mass Production

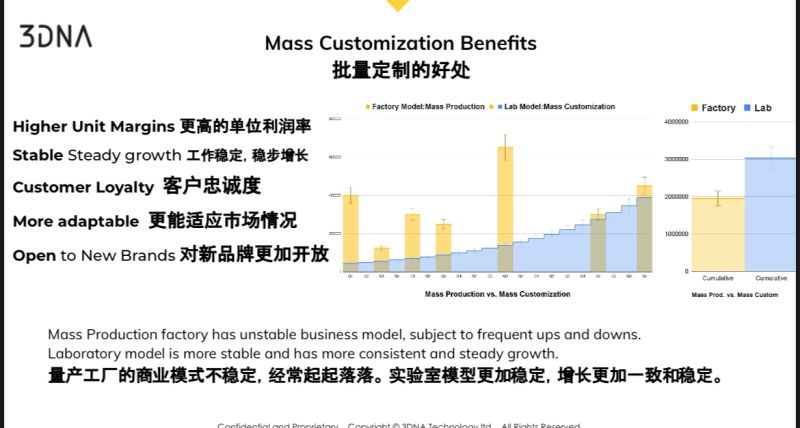

Major eyewear brands have long struggled with the consequences of mass production. Key pain points such as inventory capitalization, logistics, and product depreciation are not just operational hurdles—they are deeply embedded in the very nature of how eyewear is produced and distributed. When eyewear is manufactured in bulk, the costs tied to unsold inventory and logistical complexity can become unsustainable, especially in a rapidly changing marketplace where consumer preferences evolve quickly.

The 3DNA Solution: Mass Customization at Scale

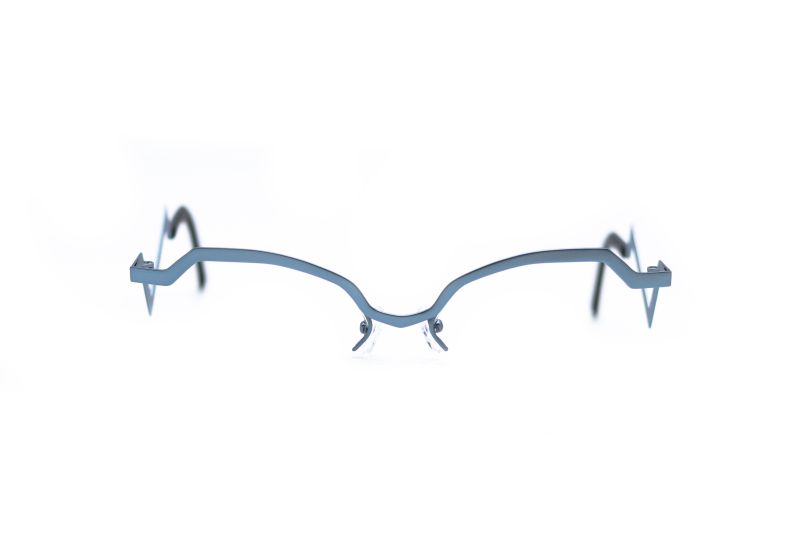

While there may never be a perfect solution to every challenge, 3DNA identified that a mass customization model could offer a powerful and scalable alternative. Instead of producing a large volume of stock and hoping it matches consumer demand, mass customization focuses on producing eyewear tailored to the specific needs and preferences of each customer—effectively reducing waste, enhancing customer satisfaction, and optimizing the supply chain.

To achieve this, 3DNA has standardized and unified both design parameters and production methods, building a truly end-to-end mass customization platform. This ambitious approach is designed to absorb the largest possible volume of eyewear production, enabling flexibility without sacrificing efficiency.

Tackling Bottlenecks with Proprietary Technology

However, transitioning from mass production to mass customization is no small feat. The current state-of-the-art manufacturing systems face several bottlenecks—especially around integration, communication between stakeholders, and adapting to variable designs at scale.

3DNA has directly addressed these bottlenecks by developing proprietary technologies, including a hardware-integrated software platform. This platform is built to orchestrate the entire ecosystem of eyewear production—from consumers and retailers to brands, manufacturers, and material suppliers. Every user type interacts within a synchronized environment, drastically improving communication, accuracy, and speed throughout the process.

The Future of Eyewear Is Personalized

As digital transformation sweeps across industries, 3DNA stands at the forefront of innovation in eyewear, demonstrating that mass customization is not just feasible—it’s necessary. By solving long-standing challenges with fresh thinking and cutting-edge technology, the company is setting a new standard for how eyewear should be designed, manufactured, and delivered in the modern age.

The journey from concept to solution has been long but purposeful. With its robust technology platform and visionary approach, 3DNA is not just changing how eyewear is made—it’s redefining what’s possible.